Researcher from Tampere University customizes 3D bioprinting materials for biomedical purposes

Hatai Jongprasitkul, a researcher from the Biomaterials and Tissue Engineering Group at Tampere University, has successfully defended his doctoral thesis on customising 3D bioprinting materials for biomedical purposes on the 20th of October, 2023.

Jongprasitkul completed his BSc in Biomedical Engineering in Thailand before exploring study opportunities worldwide. Eventually, he chose Tampere University because of its renowned educational system, supportive research environment, and excellent facilities. With his background in tissue engineering, biomaterials, and biophysics, he pursued a Master’s program and later a Doctoral degree in Biomedical Sciences and Engineering.

During his Master’s degree, Jongprasitkul focused on creating implant biomaterials for patients with eye disease. However, after listening to a lecture on 3D printing for skin regeneration by Prof. Gordon Wallace from the University of Wollongong, Australia, he decided to explore the field of biomaterials for medical 3D printing.

Jongprasitkul’s research focused on developing novel hydrogel materials for 3D printing of living cells. He collaborated with Dr Vijay Singh Parihar and Dr Sanna Turunen, who are experts in polymer chemistry and biomaterial fabrication. Prof. Minna Kellomäki co-supervised Jongprasitkul’s PhD together with Dr Parihar and Dr Turunen. In total, they published five scientific papers and are currently working on two more.

The materials in which cells are 3D printed for medical purposes require a very high water content. Hydrogels, which are naturally high in water, are therefore used as the printing “ink”. These so-called bioinks require extensive work in tuning the chemistry so that the cells stay alive during the printing process and that the end product, a skin graft, for instance, stays in the required shape.

“You put water into a bottle, it becomes the bottle… Be water, my friend,” Jongprasitkul quotes Bruce Lee.

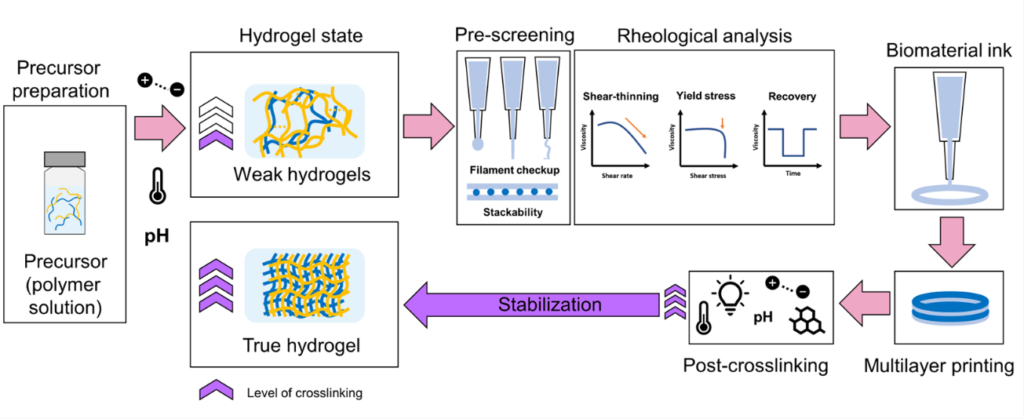

Jongprasitkul’s PhD work produced in-depth knowledge of the flow behavior of bioinks so that they would be suitable for injecting, molding or 3D printing. Furthermore, various printability assessment methods were gathered to ensure that these newly developed inks would meet the minimum requirements for the extrusion printing method (Figure 1).

For tuning the hydrogels, Jongprasitkul chemically modified them with different organic molecules that would not harm living cells or tissues (Figure 2). Moreover, different types of polymers and their functionalisation were examined to assess a wide range of crosslinking techniques. Among them, methacrylation and catechol conjugation were the most prominent. The use of temperature-induced gelation is particularly prevalent in polypeptide-based biomaterial inks like gelatin and collagen, while the printability of alginate and gellan gum-based biomaterial inks can be improved through ionic crosslinking. Another effective strategy involved using catechol-conjugated biomaterial inks that can facilitate metal-catechol complexes and hydrogen bonding triggered by pH changes.

Overall, Jongprasitkul’s work has opened up a wide range of possibilities, from injectable to adhesive hydrogels, in the field of bioprinting. His PhD thesis and link to an interview about his doctoral journey can be found on the Tampere University website.

Author: Sanna Turunen

Photos: Vijay Singh Parihar

Figure: Hatai Jongprasitkul

Links

The doctoral dissertation is available online: https://trepo.tuni.fi/handle/10024/151414

Read more about Hatai Jongprasitkul’s thoughts on his journey to a PhD: https://research.tuni.fi/coeboc/news/action-equals-reaction-hatai-jongprasitkuls-journey-to-a-phd/

Keywords

3D bioprinting, biomaterial ink, hydrogel materials, tissue engineering, crosslinking techniques, printability screening